Alloy nuv hla t bar yob txoj kev tshuab

Txheej Txheem Ua Haujlwm Flow

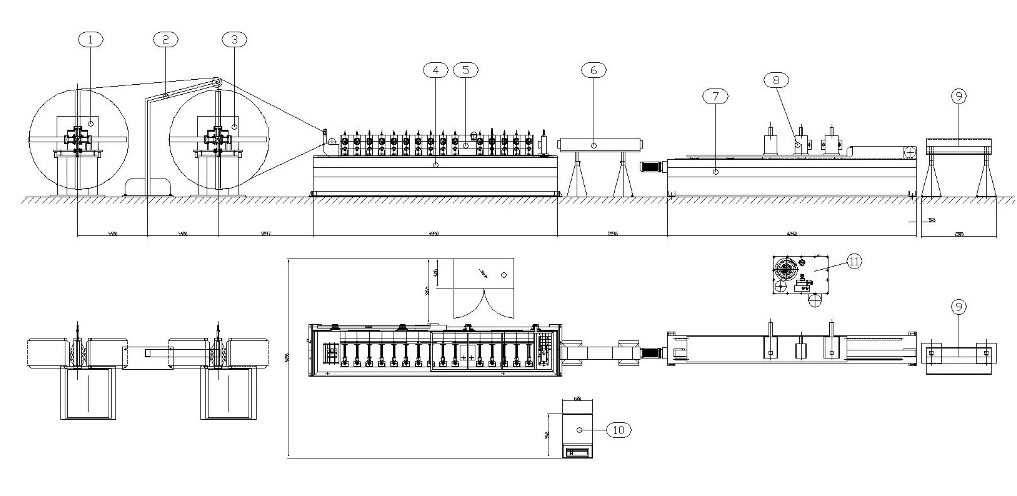

| TSIS MUAJ. | Cov Npe | Ntau |

| 1 | Ob chav motorized de-coiler (xim steel kauj) | 1 |

| 2 | Chav tsev cia rau xim hlau | 1 |

| 3 | Ob chav motorized de-coiler (galvanized steel kauj) | 1 |

| 4 | Chav tsev cia rau galvanized steel | 1 |

| 5 | Roll qub unit ntawm lub hauv paus | 1 |

| 6 | T-bar cov menyuam sib sau ua ke Gearbox COMBI | 1 |

| 7 | Txiav rooj puag | 1 |

| 8 | Punching tuag.8PC (6+2) | 1 |

| 9 | Control Vaj Huam Sib Luag (Electric Control System) | 1 |

| 10 | Chaw nres tsheb Hydraulic Siv Servo lub cev muaj zog 7.5kw | 1 |

| 11 | Alloy nuv riveting tshuab | 1 |

Alloy nuv ntoo khaub lig T-shaped steel bar yob txoj kev tshuab yog ib tug tshwj xeeb yob txoj kev tshuab tshwj xeeb uas tsim los rau zus tau tej cov alloy nuv T-zoo li tus ntoo khaub lig steel tuav.Cov ntsia hlau no feem ntau yog siv los tshem tawm cov ceilings hauv cov tsev lag luam thiab cov tsev nyob.Lub tshuab ua haujlwm los ntawm kev pub ib lub kauj hlau rau hauv cov txheej txheem ntawm cov chais uas maj mam ua thiab txiav cov hlau mus rau qhov xav tau T-bar profile.Alloy hooks tau ntxiv thaum lub sij hawm molding thiab kev koom ua ke rau hauv T-bar los muab kev ruaj ntseg kev sib txuas rau qab nthab mounts.Lub tshuab yog automated heev thiab tuaj yeem tsim T-bars ntawm kev kub ceev, ua rau nws ua tau zoo rau kev tsim khoom loj.

● 1 xyoo lav rau cov khoom seem yog suav nrog cov lus hais.

● Kev cob qhia cov neeg ua haujlwm hauv peb lub Hoobkas yog dawb.

● Tus kws tshaj lij tuaj yeem raug xa mus rau kev teeb tsa thiab kev cob qhia tus neeg teb xov tooj ntawm qhov chaw, tab sis tus nqi yuav tsum sib tham nyias.