Sihua Cable Tais Yob txoj Tshuab

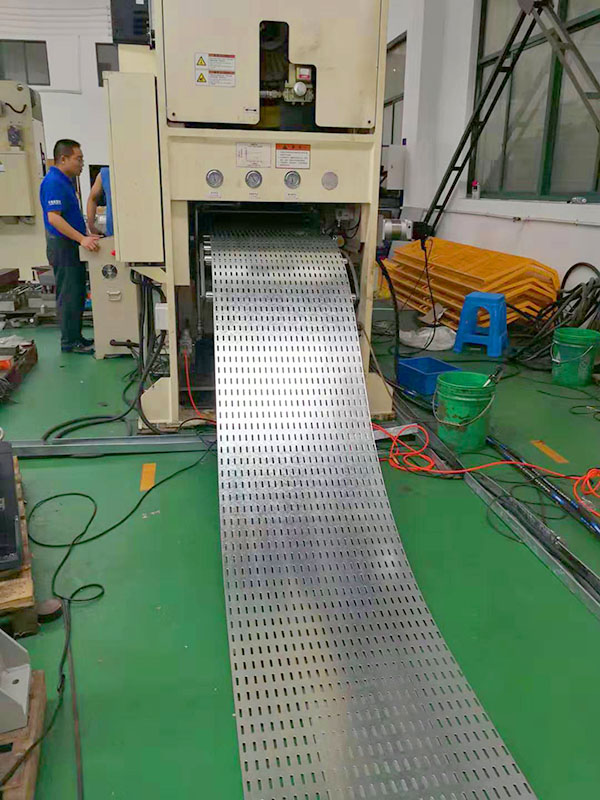

Cable tais yob txoj kev tshuab (tseem hu ua cable ladder yob txoj kev tshuab) muaj peev xwm ua ntau qhov sib txawv ntawm cable tais los ntawm kev hloov cov punching pwm. Cov kab hluav taws xob uas tsim los ntawm lub tshuab yob txoj kab no yog siv dav hauv cov chaw tsim khoom thiab lwm lub tsev. Vim lawv qhov tseeb robustness. Cable tais yob txoj kev tshuab muaj decoiler (uncoiler), tawm tshuab (leaver), servo pub khoom, xuas nrig ntaus system, pem hauv ntej txiav ntaus ntawv, guiding device, yob qub, rear straightening ntaus ntawv thiab khiav-tawm rooj.

Nrog rau tag nrho thiab tshwj xeeb kev paub, peb tuaj yeem hloov kho cable tais yob txoj kev tshuab lossis cable tais yob txoj kab ntau lawm raws li cov neeg siv khoom "profile drawings thiab specifications.

| Lub npe | Chav tsev | Ntau | |

| Decoiler | Teeb | 1 | |

| Main Tshuab | Qiv, Feeder, | Teeb | 1 |

| txoj kev tshuab | Teeb | 1 | |

| Cov cuab yeej txiav | Teeb | 1 | |

| Hydraulic system | Teeb | 1 | |

| Hluav taws xob tswj qhov system | Teeb | 1 | |

| Ntim rooj | Teeb | 1 | |

1. Italian tshuab German zoo yob txoj kev tshuab.

2. Kev kub ceev high precision yob txoj kev tshuab rau koj qhov profile zoo heev.

3. Hom tshuab no muaj qhov zoo tshaj plaws thiab tus nqi zoo tshaj plaws. Nws muaj qhov ntsuas qhov tseeb thiab ua haujlwm yooj yim.

4. Peb tuaj yeem tsim thiab tsim lub tshuab tshwj xeeb raws li cov neeg siv khoom xav tau thiab peb tuaj yeem muab kev cob qhia, kev tsim khoom, kev teeb tsa, kev debugging thiab kev pabcuam rau txhua tus neeg siv khoom.

5. Peb cov khoom tau raug xa tawm mus rau ntau thaj tsam thiab yeej lub koob npe nrov vim tias muaj txiaj ntsig zoo thiab muaj txiaj ntsig zoo.

Lub perforated Cable Tray Roll Forming Tshuab yog duplex thiab kev ua haujlwm siab ntau lawm kab rau kev tsim C seem profile nrog slotted qhov rau kev txhawb nqa hluav taws xob thaiv hauv kev lag luam thiab kev tsim kho. Lub tais cable uas tau tsim los ntawm Cable Tray Roll Forming Tshuab feem ntau yog tsim los ntawm nruab nrab ntsuas steel thickness ntawm 0.8 ~ 2.0mm.

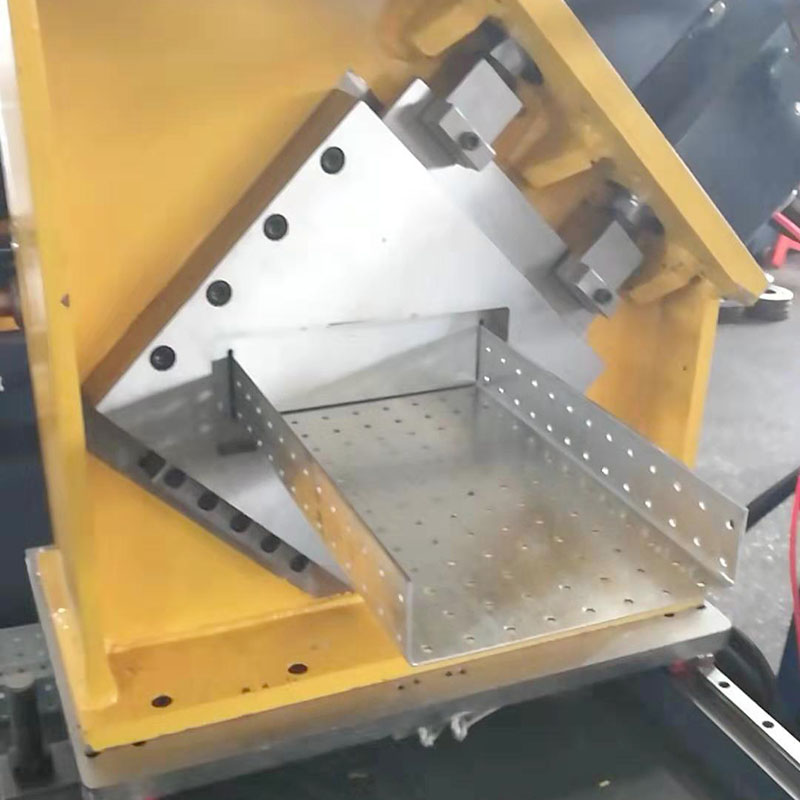

Lub perforated Cable Tray Roll Forming Tshuab ua tiav kev sib koom ua ke hydraulic xuas nrig ntaus lossis kev kub ceev xovxwm tshuab rau hluav taws xob qhov ntawm cable tais. Tsis tas li ntawd, lub telescope ncej muaj rau kev hloov pauv sai yam tsis muaj kev hloov pauv. Pre-txiav los yog tom qab txiav tau ob qho tib si nruab rau kev txiav cov khoom tiav.

Ib qho tag nrho Cable Tais Yob txoj Tshuab nrog rau Decoiler, Cov cuab yeej qhia, Ncaj chais, Main Roll Forming Tshuab, Hydraulic system, PLC tswj qhov system thiab cov rooj khiav tawm. Peb yob txoj kev tshuab nruab nrog lub computer tswj system. Koj tsuas yog xav tau kev pab cuam hauv lub khoos phis tawj cov khoom thiab qhov ntev uas koj xav tau, ces lub tshuab yob txoj kev tsim nws txiav. Lub tshuab ua haujlwm yooj yim, thiab ua haujlwm ruaj khov.

| Haum Plate Khoom | |

| Khoom - thickness | 0.8-2.5 hli |

| Cov khoom nyoos | Galvanized hlau thiab dub steel ntawv |

| Ua hauj lwm ceev | 15m / min |

| Tsim cov kauj ruam | 8 chaw nres tsheb |

| Khoom siv ntawm Roller | cr12 mav |

| Khoom siv ntawm Shaft | 45 # Advanced Steel (inch: * 90mm), thermal refining |

| Tsav system | gearbox tsav, shafts txoj kab uas hla 70mm |

| Main Power nrog reducer | 22 KW SIEMENS |

| Txiav | Hydraulic Txiav tawm |

| Khoom siv ntawm cov hniav txiav | SKD11 (JAPAN) |

| Hydraulic chaw nres tsheb fais fab | 11 KW SIEMENS |

| Lub tshuab tag nrho yog tswj los ntawm kev lag luam computer-PLC | |

| PLC--Mitsubishi Nyiv | |

| Kov Screen—KINCO | |

| Cov khoom siv hluav taws xob--Schneider | |

| Kho qhov siab los ntawm cov motors thiab cov ntsia hlau, tswj los ntawm PLC | |

Daim duab ntawm cable tais tshuab