Hydraulic tsis siv neeg unwinding decoiler

Cov ntsiab lus tseem ceeb:

1. Material Compatibility:

Haum rau cov hlau (steel, aluminium, tooj liab) los yog lwm yam ntaub ntawv (films, ntawv, plastics) nyob rau hauv lub thickness ntawm 0.4-1.3 hli.

2. Slitting Width Range:

Input Coil Dav: Mus txog 1300mm (tuaj yeem kho raws li qhov yuav tsum tau ua).

Output Sawb Dav: Kho tau (xws li, 10mm-1300mm), nyob ntawm seb muaj pes tsawg tus slitting hniav.

3. Tshuab Hom:

Rotary Slitter (rau cov ntaub ntawv nyias xws li foils, zaj duab xis, lossis cov ntawv hlau nyias).

Loop Slitter (rau cov ntaub ntawv tuab lossis tawv).

Razor Slitting (rau cov ntaub ntawv hloov tau zoo li ntawv lossis yas zaj duab xis).

4. Txoj kev Slitting:

Razor Blade Slitting (rau cov ntaub ntawv mos / nyias).

Shear Slitting (rau qhov tseeb txiav hauv cov hlau).

Crush Cut Slitting (rau cov ntaub ntawv tsis-woven).

5. Uncoiler & Recoiler Peev Xwm:

Max Coil Nyhav: 5-10 tons (kho raws li qhov xav tau ntau lawm).

Hydraulic lossis Pneumatic Expansion Shafts rau kev ruaj ntseg coil tuav.

6. Kev tswj nruj:

Tsis Siv Neeg Tension Control (sib nqus hmoov nres, servo lub cev muaj zog, lossis pneumatic).

Lub Vev Xaib Qhia Txheej Txheem rau kev ua kom raug (± 0.1mm).

7. Ceev & Productivity:

Kab Ceev: 20-150 m / min (kho tau raws li cov khoom siv).

Servo-tsav rau siab precision.

8. Hniav Khoom & Lifespan:

Tungsten Carbide los yog HSS Hniav rau hlau slitting.

Quick-Hloov Hniav System rau tsawg kawg downtime.

9. Tswj System:

PLC + HMI Touchscreen rau kev ua haujlwm yooj yim.

Nws pib dav & qhov chaw hloov kho.

10.Safety Nta:

Kev nres thaum muaj xwm txheej ceev, kev tiv thaiv kev nyab xeeb, thiab kev tiv thaiv overload.

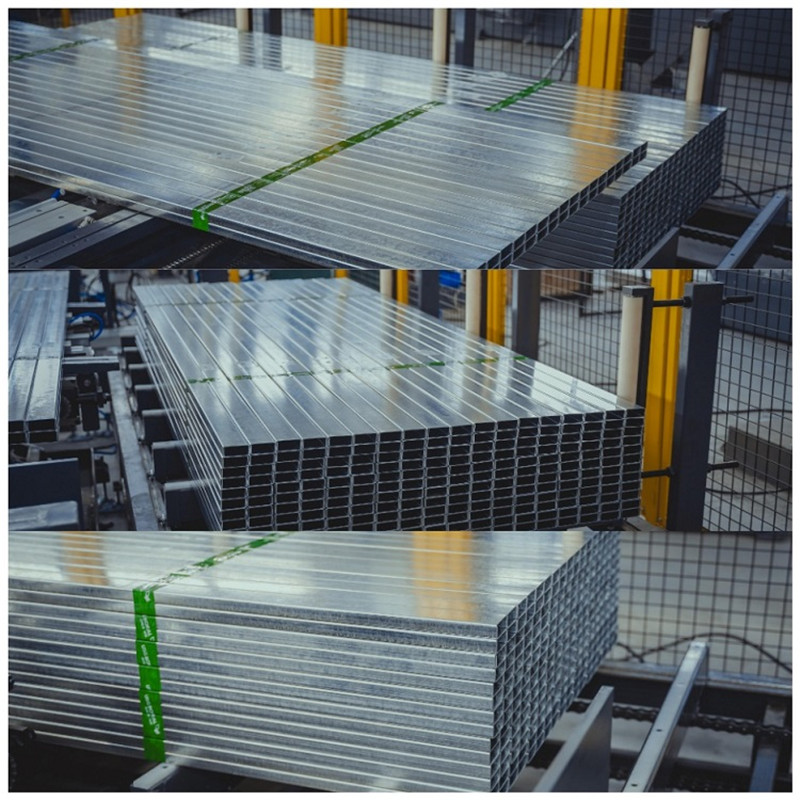

Haum rau kev tsim cov profiles ≥1700Mpa

Haum rau kev tsim cov profiles ≥1500Mpa

Tsheb pem hauv ntej tiv thaiv kev sib tsoo beam-bending pwm 1

Tsheb pem hauv ntej tiv thaiv kev sib tsoo beam-bending pwm 2

Anti-kev sib tsoo beam dov khoov mechanism 1

Anti-kev sib tsoo beam dov khoov mechanism 2