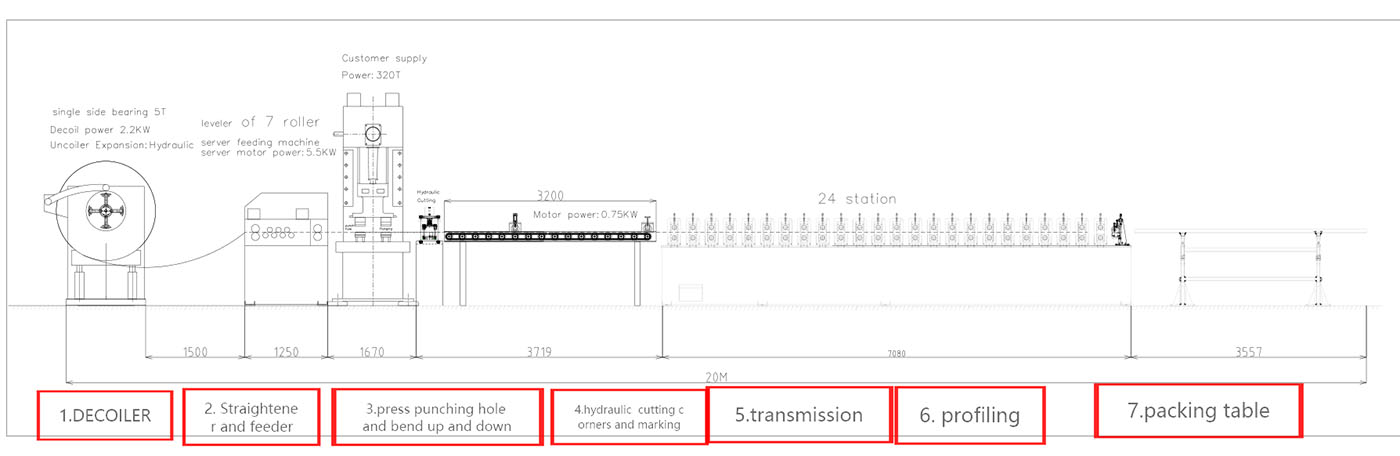

Tsis siv neeg zoo 10-25m / min sib sau ceev tswj cable tais yob txoj kev tshuab

| 5 tuj hydraulic De-coiler | Txoj kab uas hla: 420-560mm hydraulic expansion. Cov duab rau siv Expansion: Hydraulic de-coiler Peev xwm: 5000kg ib mandrel Max Coil Dav: 1250mm |

| Leveling ntaus ntawv | 1.7 rolls leveling, 3 yob nce thiab 4 yob down 2.Txoj kab uas hla yog Ø 80mm, chrome thiab HRC60 kev kho cua sov kom ruaj ntseg zoo 3.Leveling Raw Khoom thickness: 1.5-2.5mm 4.Max Leveling Raw Khoom dav: 1000mm |

| Khoom noj khoom haus | Pub Servo noj lub cev muaj zog: txog 4.4KW, Yaskawa Nqe lus piav qhia: servo pub mis tuaj yeem tswj tau qhov kev sib tsoo ntawm qhov tseeb, tswj los ntawm PLC, thiab kev pub mis ntev tuaj yeem yog +-0.05mm, servo lub cev muaj zog tuaj yeem tswj tau qhov nrawm, thiab tuaj yeem lees txais cov teeb liab tawm tswv yim, thiab hnov mob sai, thiab ua haujlwm tau zoo, lub vijtsam kov tuaj yeem tso saib qhov kev sib hloov ceev, qhov ntev thiab qhov ntau, nws tuaj yeem tswj tau los ntawm phau ntawv thiab nws pib. |

| Punching xovxwm tshuab | 1 Series JH21-160 Lub npe: Yangli |

| Main yob txoj kev tshuab | Khoom siv phaj haum: Khoom thickness: 1.0-2.5mm Cov khoom siv raw: Galvanized steel thiab dub steel ntawv Ua hauj lwm ceev: 10-25meters / min Tsim Cov Kauj Ruam: 18 chaw nres tsheb Khoom siv ntawm cov menyuam: CR12MOV nqus cua sov kho 58-62HRC Bearing: NSK Nyiv Tsav system: iav kem, shafts txoj kab uas hla 70mm Lub zog loj nrog reducer: 22KW SIEMENS Txiav: Hydraulic Txiav Khoom siv ntawm cov hniav: SKD11 (Nyiv) Hydraulic Chaw nres tsheb fais fab: 11KW SIEMENS |

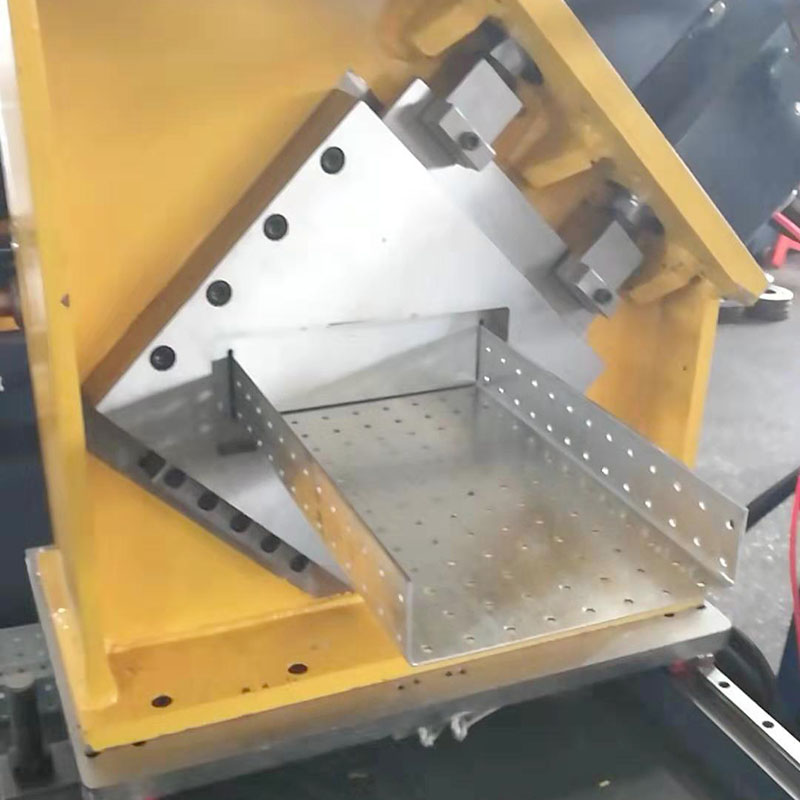

| Hydraulic txiav system | Cov khoom siv cutter: SKD11 HRC58-62 degree Txiav tom qab sib sau: Txiav daim ntawv tom qab yob txoj kev kom ntev ntev Kev txiav tawm: Lub tshuab tseem ceeb tau nres thiab txiav yuav tshwm sim. Tom qab txiav, lub tshuab tseem ceeb yuav pib pib. Khoom siv: SKD11 VACUUM HEATTREATMENT 60-62HRC Length ntsuas: nrhiav tus pin tsau txiav tawm ntawm ob kab qhov Ntev ntev: 6m +/- 1mm |

| Tswj vaj huam sib luag | (1) Fais fab mov: 380V, 50 Hz, 3Phase (hloov raws li qhov kev thov) (2) Ntev & kom muaj nuj nqis ntsuas tau; (3) Ntev & ntau tswj los ntawm PLC (4) Qhov ntev tsis raug tuaj yeem hloov kho tau yooj yim. (5) Tswj vaj huam sib luag: khawm-hom hloov thiab kov npo (6) Cov lus hauv lub vijtsam kov: Lus Askiv thiab Suav (7) Chav ntsuas qhov ntev: millimeter (hloov rau ntawm cov tswj vaj huam sib luag) |

| Tsis muaj. | Yam khoom | Ntau |

| 1 | Uncoiler | 1 Teeb |

| 2 | Servo Feeder | 1 Teeb |

| 3 | Hydraulic Punching Device | 1 Teeb |

| 4 | Cable Tais Roll Former | 1 Teeb |

| 5 | Hydraulic Txiav | 1 Teeb |

| 6 | Chaw nres tsheb Hydraulic | 1 Teeb |

| 7 | Lub rooj khiav | 2 Teeb |

| 8 | PLC Tswj System Txee | 1 Teeb |

Cov kev pabcuam yog dab tsi?

Peb muab kev txhawb nqa rau tag nrho lub neej.

Lub caij no, yog tias ib qho twg puas lawm thiab tsis muaj kev puas tsuaj, peb yuav xa cov tshiab rau koj dawb.

Thaum xav tau tus kws kho mob mus txawv tebchaws, peb yuav npaj tus kws kho mob.

Tab sis tus neeg yuav khoom yuav tsum tau them tag nrho cov nqi, suav nrog Visa, Daim pib ncig mus ncig,haum kev pab thiab them tus nqi kev pab cuam rau tus kws kho mob nrog $100/hnub.

Peb yog lub Hoobkas nrog ntau tshaj 10 xyoo kev paub txog kev tsim Roll Forming Machine.

Peb muaj peb tus kheej muaj zog tshawb fawb thiab kev loj hlob pab neeg.

Peb muaj ntau tshaj 15 tus kws tshaj lij.

engineers nrog ntau tshaj 20 xyoo kev paub.

Peb muaj advanced Laser Tej Tshuab, CNC Machining Center, Polishing Line, Painting Kab, thiab lwm yam. Cov khoom siv siab heev tau lees tias qhov zoo ntawm txhua qhov thiab cov tsos ntawm peb cov tshuab.

Peb cov cav tov tau mus txog International Inspection Standards.